History of Electricity

600BC: A mathematician in Greece named Thales (one of the 7 sages of Greece) is thought to be the first person to discover what we know as static electricity by rubbing amber with animal fur.

Late 1500s: An English scientist, William Gilbert (one of Queen Elizabeth’s physicians) found out that amber was not the only conductor. He added many more substances to the list and coined the term electricity.

Early 1700s: Stephen Gray discovered conductivity and that even water could be electrified. Charles Du Fray, in Paris, performed experiments based on Gray’s work and came to the conclusion that everything and everybody contained electricity (leaving out lightning, ironically).

1752: Ben Franklin conducted his famous kite experiment. In the process, he proved that pointed rods conduct electricity better than balls do and that lightning is a form of electricity. Franklin then invented lightning rods and sold them throughout colonial America.

1870s: Thomas Edison built a DC (direct current) electric generator in America and later provided all of New York’s electricity.

1879: FIRST FATAL ACCIDENT DUE TO ELECTRIC SHOCK.

1800s: Nikola Tesla invented the AC (alternating current) system for electrical transmission. This is what is used today over DC due to its many advantages; the biggest is that you can generate much more power from AC than DC. He also invented motors that run on AC and designed the world’s first Hydroelectric Plant.

The short answer to “What is electricity?” as OSHA states it, is the flow of electrons though a conductor. Since atoms make up any and everything, and electrons are particles that make up an atom, electrons are therefore everywhere. Because of this, electricity is everywhere. We are going to discuss how this affects us and how it is paramount to take a few extra steps in our daily lives and remember a few tips to keep ourselves safe with regards to electricity and electrical apparatuses.

The short answer to “What is electricity?” as OSHA states it, is the flow of electrons though a conductor. Since atoms make up any and everything, and electrons are particles that make up an atom, electrons are therefore everywhere. Because of this, electricity is everywhere. We are going to discuss how this affects us and how it is paramount to take a few extra steps in our daily lives and remember a few tips to keep ourselves safe with regards to electricity and electrical apparatuses.

Electricity is conducted through some materials better than others. Returning for a moment to the definition given earlier about electricity being the flow of electrons through a conductor, we know that conductors are materials that loosely hold electrons. Great examples of these are most metals: copper, aluminum, or steel. Other things hold electrons very tightly, these are called insulators. Insulators include: rubber, cloth, plastic, glass, or dry air.

Electricity has a few important properties:

- It must have a complete path (or circuit) to continuously flow.

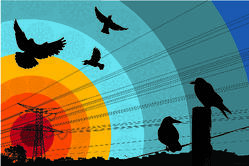

- Without two points of contact on the body for current to enter and exit, respectively, there is no hazard of shock. In fact, this why birds and squirrels can sit on power lines; there's only one point of contact!

- It will all paths back to the source, but it will follow paths proportionally according to the conductivity of each path.

- When impedance (resistance to electrical currents) increases even slightly, the electrical current seeks other paths to ground, such as through a person in contact with an energized surface.

As electricity is a serious workplace hazard, exposing employees to electric shock, burns, fires, and explosions, it is very important to understand how to avoid these risks and learn how to reduce electrical accidents down to 0.

The good news is that these electrical accidents are 100% preventable with proper knowledge and training!

In short, there are only 3 things needed to achieve this.

- Understanding how electricity works.

- Recognizing potential electrical hazards.

- Learning about safety devices that prevent shock.

All three of these things are taught (and then some) in Safety Training Service’s NFPA 70E training course. For more information contact us and find out more information. For anyone not interested in the training at this time, read on for more information/tips on reducing these risks in your workplace.

Electrical equipment used in an office is potentially hazardous. It can cause serious shock and burn injuries if improperly used or if equipment is poorly maintained. Remember, periodic self-inspection should be conducted of your area to help identify and correct electrical hazards and maintain compliance. Follow these tips to reduce exposure to electrical hazards.

- To reduce the risk of fires, turn off all appliances at the end of the day.

- Only use 3-prong (grounded) outlets and grounded appliances.

- Immediately disconnect any malfunctioning electrical equipment or any equipment giving off a strange odor.

- Promptly disconnect and replace cracked, frayed, or broken electrical cords.

- Don't "yank" cords out by pulling on the cord itself.

- Keep extension cords clear of doorways and other areas where they can be stepped on.

- Do not use staples to fasten extension cords. Do not hang cords from nails, or suspend by wire.

- It is recommended to keep all wires and cords off the floor to prevent injuries caused by tripping.

- Don't use equipment with worn or frayed cords or cables.

- Ensure that unsafe electrical conditions and practices are promptly reported to a supervisor.

- Never force a plug into an outlet if it doesn't fit!

- Plugs should fit securely into outlets, but check for those that have loose-fitting plugs, which can overheat and lead to fire.

- Ensure that all appliances are certified by an independent testing lab! E.g., Underwriter's Laboratory (UL).

- Maintain at least 3 feet of clearance in front of all electrical panels. (Overlooked way too often!)

- Water and electricity should never be very close to each other.

- Electric plugs at cubicles should be away from places where water or coffee spills are most likely to occur.

- Inspect space heaters!

- Verify the devices are approved for commercial use and have a switch that automatically shuts off the heater if the heater is tipped over. Further, make sure space heaters are not powered through an extension cord or placed near combustible materials such as paper.

- Never block fire sprinklers!

- Furniture and tall stacks of materials can block the range of fire sprinklers, reducing their effectivemess in the event of an emergency.

- Do not block escape routes or prop open fire doors.

- Items should never be stored along an emergency exit route. These paths should remain free from clutter, according to OSHA. Fire doors should not be held open by unapproved means (such as with a garbage can or a chair), as this creates a significant fire hazard.

A

A  According to the Surgeon General,

According to the Surgeon General,

job. In ancient times, it was tying rocks or bones to sticks for use as a hammer or sharpened to make hunting easier. Essentially, they established that using crude items could be used to make life easier. Ergonomics is just that, an applied science (not just a buzzword for marketers!) of work. That is, it’s intended to maximize productivity of workers by reducing/eliminating fatigue or discomfort. The literal definition of ergonomics, as Dictionary.com states, is “the study of the relationship between workers and their environment.” Also known as “biotechnology,” and first coined by Wojciech Jastrzebowski in 1857.

job. In ancient times, it was tying rocks or bones to sticks for use as a hammer or sharpened to make hunting easier. Essentially, they established that using crude items could be used to make life easier. Ergonomics is just that, an applied science (not just a buzzword for marketers!) of work. That is, it’s intended to maximize productivity of workers by reducing/eliminating fatigue or discomfort. The literal definition of ergonomics, as Dictionary.com states, is “the study of the relationship between workers and their environment.” Also known as “biotechnology,” and first coined by Wojciech Jastrzebowski in 1857.

mechanical compression, or sustained or awkward positions."

mechanical compression, or sustained or awkward positions."