"Moving machine parts have the potential to cause severe workplace injuries, such as crushed fingers or hands, amputations, burns, or blindness. Safeguards are essential for protecting workers from these preventable injuries. Any machine part, function, or process that may cause injury must be safeguarded. When the operation of a machine or accidental contact injure the operator or others in the vicinity, the hazards must be eliminated or controlled."

--OSHA on "Machine Guarding"

5 Most Common Ways of Machine Guarding

- Barrier Guards

- Presence Sensing Devices (PSD)

- Pullbacks/Restraints

- Two-hand Controls/Two-hand Trip

- “A” and “B” Gates

Barrier Guards

These are designed to keep the operator’s hands and arms from entering the “danger zone” as prescribed by the particular machine. They are appropriate safeguards for full revolution and part revolution mechanical power presses. They are usually the first point-of-operation safeguard considered for machines.

These are designed to keep the operator’s hands and arms from entering the “danger zone” as prescribed by the particular machine. They are appropriate safeguards for full revolution and part revolution mechanical power presses. They are usually the first point-of-operation safeguard considered for machines.

Regulation: 29 CFR 1910.217

- Barrier guards on power presses must prevent the entry of hands or fingers into the point of operation by reaching through, over, under or around the guard.

- The barrier guards must conform to maximum permissible openings tables.

- The barrier guard itself must not create pinch points between the guard and moving machine parts.

- The guard must not be easily removable.

- The guard must not interfere with machine inspection.

- The barrier guard must offer maximum visibility of the point of operation consistent with the other requirements.

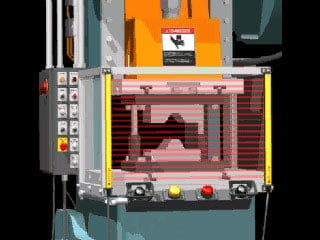

Presence Sensing Devices

These are designed to automatically stop the machine stroke if sensing field is interrupted. Proper use provides protection not only for operators but also for other employees in the area. They are one of the most common safeguards for automatic feed part revolution clutch presses, and have many requirements that must be met before they can be installed as point-of-operation safeguards.

Proper use provides protection not only for operators but also for other employees in the area. They are one of the most common safeguards for automatic feed part revolution clutch presses, and have many requirements that must be met before they can be installed as point-of-operation safeguards.

Regulation: 29 CFR 1910.217

- Presence sensing devices (PSD) cannot be used on machines using full revolution clutches.

- A PSD must protect the operator by preventing or stopping normal stroking of the press if the operator’s hands are inadvertently placed in the point of operation. The PSD must also be interlocked into the control circuit so that the slide motion will stop the downstroke from continuing if any part of the operator's body is within the sensing field at that time.

- Guards must be used to protect all areas of entry to the point of operation not protected by the PSD.

- PSDs cannot be used as a tripping means to initiate slide motion.

- Should a failure occur within the system, the PSD must be constructed so that the normal stopping action is still applied when required, but prevents the start of the next stroke until the failure is corrected. The failure must be indicated by the system.

- “Muting” or bypassing of the PSD during the upstroke of the press slide is permitted for parts ejection, circuit checking, and feeding.

- The safety distance from the sensing field to the point of operation must be greater than the distance determined by the safety distance formula.

Pullbacks/Restraints

Pullbacks

These are safeguarding devices on both full and part revolution power presses. They are similar to restraints, but are designed to pull the operator’s hands away from the area of the closing dies (point of operation) during each stroke of the power press.

Regulation: 29 CFR 1910.217

Attachments must be connected to and operated by the press slide or upper die.

Attachments must be connected to and operated by the press slide or upper die.- Attachments must be adjusted to prevent the operator from reaching into the point of operation or to withdraw the operator’s hands from the point of operation before the dies close.

- A separate pullout device must be provided for each operator if more than one operator is used on the press.

- Each pullout device in use must be inspected and checked for proper adjustment at the start of each operator shift, following a new die set-up, and when operators are changed. Necessary maintenance or repair on both must be performed and completed before the press is operated.

- Inspection and Maintenance Records. It is the responsibility of the employer to make periodic and regular safety inspections and keep accurate records of them.

Restraints

Sometimes referred as “holdouts,” restraints are similar to pullbacks and are appropriate safeguards for both full and part revolution mechanical power presses. When properly anchored, restraints are adjusted so that the operator can never reach the point of operation. The size and type of restraint depends on the size and type of press.

Regulation: 29 CFR 1910.217

- A holdout or a restraint device must protect the operator by preventing the operator from inadvertently reaching into the point of operation at all times and must include attachments for each of the operator’s hands.

- Attachments must be securely anchored and adjusted and separate set of restraints must be provided for each operator if more than one is required on a press.

Two-hand Controls/Two-hand Trip

Two-hand Controls

These are safeguarding devices in the single stroke mode of operation on part revolution clutch presses. It is similar to the two-hand trip; this device keeps the operators hands away from the point of operation during the entire machine stroke.

Regulation: 29 CFR 1910.217

- Press operations requiring more than one operator must provide each

operator with separate two-hand controls where each set must be engaged to complete a machine stroke. The removal of a hand from any control button will stop the slide.

operator with separate two-hand controls where each set must be engaged to complete a machine stroke. The removal of a hand from any control button will stop the slide. - Each two-hand control must meet the construction requirements of paragraph 29 CFR 1910.217(b)(7)(v).

- The safety distance between each hand control device and the point of operation must be greater than the distance determined by the safety distance formula.

- Two-hand controls’ position must be fixed so that only a supervisor of safety engineer is capable of relocating them.

Two-hand Trip

These are safeguarding devices used on a full revolution clutch power press only. It requires the joint operation of two trigger buttons located away from the “danger zone” of the press. It is similar to two-hand controls in that it requires the operator’s hands to be away from the point of operation to activate the machine stroke, but differs in that activation of the machine stroke requires only a "trip" of the controls whereas a two-hand control requires continued pressure.

Regulation: 29 CFR 1910.217

- When used in press operations requiring more than one operator, separate two hand trips must be provided for each operator, and must be designed to require concurrent application of both operators to activate the slide.

- A two-hand trip shall have the individual operator's hand controls protected against unintentional operation and have the individual operator's hand controls arranged by design and construction and/or separation to require the use of both hands to trip the press and use a control arrangement requiring concurrent operation of the individual operator's hand controls.

- The safety distance between the two-hand trip and the point of operation must be greater than the distance determined by the safety distance formula.

- Like two-hand control devices, two-hand trips’ position must be fixed so that only a supervisor or safety engineer is capable of relocating the controls.

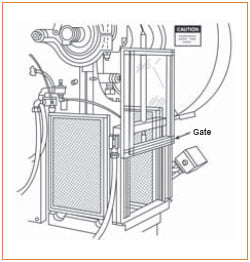

“A” Gates/”B” Gates

Type "A" and "B" Gates are both recognized methods for power press safeguarding. The "A" gate is used in both full and part revolution clutch presses while the "B" gate is for part revolution presses only.

Type “A” Gates

Type “A” Gates

These protect the operator during the entire machine stroke. This means the gate will not open until after the crankshaft rotation is complete (360°) and the machine is stopped at top dead center. Although Type "A" Gates can be used on either part or full revolution clutch presses, best safety practice is the "A" gate should be used only on full revolution clutch presses.

Type “B” Gates

These protect the operator during the downstroke only. The gate starts to open before the crankshaft rotation is complete (generally after 180° crankshaft rotation). The gates must open on the upstroke of the machine cycle before the crankshaft rotation is complete.

Regulation: 29 CFR 1910.217, 29 CFR 1910.212

- In both cases (“A” & “B” Gates), operators must be prevented from placing their hands or any other body parts in the point of operation during the die-closing portion of the press stroke.

- The guard itself must comply with applicable standards.

Owning a home may be the American dream, but it can also be a very expensive adventure. When something goes wrong or breaks, the responsibility of correcting the problem lies solely with you, rather than being paid for by a landlord. When it comes to electricity, there's more at stake than just a repair bill and a bit of inconvenience. The energy that powers all of the devices in your home and makes modern life so much simpler can also be a very real danger if you're not properly aware of how to handle it in a safe and effective manner. These ten tips are among those that homeowners should always keep in mind when dealing with electricity for the sake of safety and security.

Owning a home may be the American dream, but it can also be a very expensive adventure. When something goes wrong or breaks, the responsibility of correcting the problem lies solely with you, rather than being paid for by a landlord. When it comes to electricity, there's more at stake than just a repair bill and a bit of inconvenience. The energy that powers all of the devices in your home and makes modern life so much simpler can also be a very real danger if you're not properly aware of how to handle it in a safe and effective manner. These ten tips are among those that homeowners should always keep in mind when dealing with electricity for the sake of safety and security. If you are not already aware that the Hazard Communication is undergoing a huge change in that “

If you are not already aware that the Hazard Communication is undergoing a huge change in that “

Severe skin burns

Severe skin burns

Second degree burn:

Second degree burn: Safe work practices

Safe work practices

Luckily, many of these incidents/injuries are

Luckily, many of these incidents/injuries are  In 2008, the EPA estimated that of the 250 million tons of waste generated in the U.S., approximately one-third, or 83 million tons, was recycled or composted.

In 2008, the EPA estimated that of the 250 million tons of waste generated in the U.S., approximately one-third, or 83 million tons, was recycled or composted. produce the battery’s power.

produce the battery’s power.

As stated by OSHA, first aid is emergency care provided for injury or sudden illness before emergency medical treatment is available. The first aid provider in the workplace is someone who is trained in the delivery of initial medical emergency procedures, using a limited amount of equipment to perform a primary assessment and intervention while awaiting arrival of emergency medical services (EMS) personnel.

As stated by OSHA, first aid is emergency care provided for injury or sudden illness before emergency medical treatment is available. The first aid provider in the workplace is someone who is trained in the delivery of initial medical emergency procedures, using a limited amount of equipment to perform a primary assessment and intervention while awaiting arrival of emergency medical services (EMS) personnel. fatalities. That same year had 4.3 million total workplace injuries and illnesses, with 1.3 million resulting in days away from work.

fatalities. That same year had 4.3 million total workplace injuries and illnesses, with 1.3 million resulting in days away from work.

"Hands-on," skill based teaching methods.

"Hands-on," skill based teaching methods.

Standing on chairs – particularly

Standing on chairs – particularly

Anytime you see something unsafe, report it to your facilities management department or supervisor. Things you might want to point out include sightings of:

Anytime you see something unsafe, report it to your facilities management department or supervisor. Things you might want to point out include sightings of: An office environment is considered to be one of the safest work environments, therefore to ensure a safe work environment; each individual must employ common sense, know physical limitations, display an attentive attitude towards their surroundings, and become aware of applicable compliance codes.

An office environment is considered to be one of the safest work environments, therefore to ensure a safe work environment; each individual must employ common sense, know physical limitations, display an attentive attitude towards their surroundings, and become aware of applicable compliance codes.

The short answer to “What is electricity?” as OSHA states it, is the flow of electrons though a conductor. Since atoms make up any and everything, and electrons are particles that make up an atom, electrons are therefore everywhere. Because of this, electricity is everywhere. We are going to discuss how this affects us and how it is paramount to take a few extra steps in our daily lives and remember a few tips to keep ourselves safe with regards to electricity and electrical apparatuses.

The short answer to “What is electricity?” as OSHA states it, is the flow of electrons though a conductor. Since atoms make up any and everything, and electrons are particles that make up an atom, electrons are therefore everywhere. Because of this, electricity is everywhere. We are going to discuss how this affects us and how it is paramount to take a few extra steps in our daily lives and remember a few tips to keep ourselves safe with regards to electricity and electrical apparatuses.

A

A  According to the Surgeon General,

According to the Surgeon General,