Forklifts have been around since the very early 20th century.

Used as a practical machine to move products over short distances, they evolved from hoists and have become one of the most important, yet overlooked, industrial innovations in modern times.

World War II was a big catalyst in the development of forklifts, as the amount of goods continually being moved through that period made it a necessity for the forklifts of that time to last longer and needed to get through an eight hour day without constant recharging.

It was in the 1950s when warehouses were being built bigger and were expanded up more-so then out. With these increased lift heights, there were more concerns with safety and newer, more efficient models were being made.

Unlike cars and trucks, forklifts are often steered with their rear wheels. This increases maneuverability in tight corners, but makes for a different experience than traditional driving. Also the instability of a forklift is a noteworthy characteristic. They are rated for loads at a specified maximum weight and a specified forward center of gravity. An operator must be properly trained so as to take the load (raised or not), unit's speed, centrifugal and gravitational forces into account in order to avoid a disastrous tip-over accident. Information on load limit/loading for reference can usually be found on the forklift unit itself. Fitting it with specific safety equipment, such as a cage or a "cherry picker" (type of aerial work platform that consists of a platform or bucket at the end of a hydraulic lifting system), can also allow a forklift to be used as a personnel lift.

Safety in the Workplace:

With the intrinsic hazards associated with forklifts, there is a high need for companies to establish "rules" for the workplace to keep employees safe. Suggestions include:

Establish speed limits

Establish speed limits- Mark forklift lanes (don't forget proper signage as well)

- Drivers must yield to pedestrians

- Drivers must sound horn at any/all intersections

- Drivers of forklifts must stay a safe distance from ramps, platform edges, and other forklifts/vehicles

- Be sure to slow down and take turns slowly and safely

- Always stop before going into reverse

- Seatbelts, seatbelts, seatbelts! (make mandatory)

- Basically, operators shall:

- i. Use seatbelts at all times.

- ii. Obey traffic safety rules.

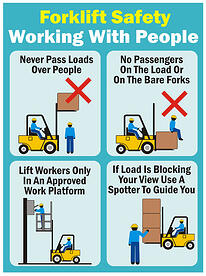

- iii. Never allow riders.

- No one is permitted to ride directly on the truck's forks.

- No one can stand or walk under elevated forklift parts, even when empty.

- Unauthorized persons may not ride on forklift trucks.

- Passengers may ride only on forklifts designed to carry them; and for elevating purposes only.

Training:

Companies must get into the habit of supplying employees with "appropriate" training on forklifts.

The American National Standards Institute (ANSI) has the most important standard with regards to forklift safety, ANSI B56. This standard is for safety requirements relating to the design, operation and maintenance of power industrial trucks (PITs). The standard is used as a guide to formulate safety rules and regulations.

ANSI B56.1-2005, Section 4.19, regarding operator training states,

"Personnel who have not been trained to operate powered industrial trucks may operate a truck for the purposes of training only, and only under the direct supervision of the trainer."

"The training program shall be presented to all new operators regardless of previous experience." ANSI B56.1-2005, Section 4.19.2

ANSI B56.1-2005, Section 4.19.4

ANSI B56.1-2005, Section 4.19.4

(a) fundamentals of the powered industrial truck(s) the trainee will operate

(b) operating environment and its effect on truck operation

(c) operation of the powered industrial truck

(d) operating safety rules and practices

(e) Operational training practice

OSHA also steps in with their regulations, under 29 CFR 191.178, for PITs.

OSHA states that training must be conducted by someone with, as OSHA puts it, "the knowledge, training, and experience to train operators and evaluate their competence." And quite simply, training shall (to mean: MUST) include:

- Formal instruction

- Practical training

- Evaluation of the trainees' performance in on-the-job situations

Forklifts are such a huge asset to us, but are dangerous pieces of machinery. Keep your eyes & minds open while working in or around them. Tell your company you want real, appropriate training before working with them. I'll leave you with what happens "when forklift training gets forgotten." The link to your REAL forklift training is below....the question is why wait until something happens to YOU?