Hazard Control Measures

The information obtained from a job hazard analysis is not worth anything unless hazard control measures recommended in the analysis are incorporated into the tasks. Not all hazard control measures are equal; some are more effective than others. Here is the order of effectiveness of hazard controls:

- Elimination/minimization of the hazard

- By substituting processes, materials, or equipment

- Changing facility design, processes, or equipment

- Enclosure of the hazard

- Enclosed cabs, enclosures over loud equipment

- Isolation of the hazard

- Interlocks, machine guards, blast shields, welding curtains

- Removal or redirection of the hazard

- Local and exhaust ventilation

Written operating procedures, work permits, and safe work practices

Written operating procedures, work permits, and safe work practices- Exposure time limitations

- (These are used most commonly to control temperature extremes and ergonomic hazards)

- Monitoring use of the more hazardous materials

- Alarms, signs, warnings

- Buddy system

- Training!

3.) Personal Protective Equipment

- Respirators, hearing protection, protective clothing, safety glasses, and hardhats

- The LAST line of defense in hazard control measures (not the first or only)

- PPE is acceptable as a control measure:

- When engineering controls are not feasible or do not completely eliminate the hazard

- If engineering controls are still being developed

- When safe work practices don't provide sufficient additional protection

- During emergencies when engineering controls may not be feasible

There may be times where you must choose to use a hazard control measure over another higher in effectiveness. An example of this may be if you needed interim protection while the hazard is abated permanently. Also, some hazards cannot be eliminated entirely, and therefore the hazard control measures may be a combination or all three types of controls.

Common Hazards and Descriptions

Chemical

|

A chemical that exposes a person by absorption through the skin, inhalation, or through the blood stream that causes illness, disease, or death. The amount of chemical exposure is critical in determining hazardous effects. Check Safety Data Sheets (SDS), and/or OSHA 1910.1000 for chemical hazard information. |

Chemical

|

A chemical that, when exposed to a heat ignition source, results incombustion. Typically, the lower a chemical's flash point and boiling point, the more flammable the chemical. Check SDS for flammability information. |

Chemical

|

A chemical that, when it comes into contact with skin, metal, or other materials, damages the materials. Acids and bases are examples of corrosives. |

Explosion

|

Self Explanatory. |

Explosion

|

Sudden and violent release of a large amount of gas/energy due to a significant pressure difference such as rupture in a boiler or compressed gas cylinder. |

Electrical

|

Contact with exposed conductors or a device that is incorrectly or inadvertently grounded, such as when a metal ladder comes into contact with power lines. 60Hz alternating current (common house current) is very dangerous because it can stop the heart. |

Electrical

|

Use of electrical power that results in electrical overheating or arcing to the point of combustion or ignition of flammables, or electrical component damage. |

Electrical

|

The moving or rubbing of wool, nylon, other synthetic fibers, and even flowing liquids can generate static electricity. This creates an excess or deficiency of electrons on the surface of material that discharges (spark) to the ground resulting in the ignition of flammables or damage to electronics or the body's nervous system. |

Electrical

|

Safety-critical equipment failure as a result of loss of power. |

Ergonomics

|

Damage of tissue due to overexertion (strains and sprains) or repetitive motion. |

Ergonomics

|

A system design, procedure, or equipment that is error-provocative. (A switch goes up to turn something off). |

Excavation

|

Soil collapse in a trench or excavation as a result of improper orinadequate shoring. Soil type is critical in determining the hazard likelihood. |

Fall

|

Conditions that result in falls (impacts) from height or traditional walking surfaces (such as slippery floors, poor housekeeping, uneven walking surfaces, exposed ledges, etc.) |

Fire/Heat |

Temperatures that can cause burns to the skin or damage to other organs. Fires require a heat source, fuel, and oxygen. |

Mechanical/Vibration

|

Vibration that can cause damage to nerve endings, or material fatigue that results in a safety-critical failure. (Examples are abraded slings and ropes, weakened hoses and belts.) |

Mechanical Failure |

Self explanatory; typically occurs when devices exceed capacity or are inadequately maintained. |

Mechanical |

Skin, muscle, or body part exposed to crushing, caught-between, cutting, tearing, shearing items or equipment. |

Noise |

Noise levels (>85 dBA 8 hr TWA) that result in hearing damage or inability to communicate safety-critical information. |

Radiation

|

Alpha, Beta, Gamma, neutral particles, and X-rays that cause injury (tissue damage) by ionization of cellular components. |

Radiation

|

Ultraviolet, visible light, infrared, and microwaves that cause injury to tissue by thermal or protochemical means. |

Struck By

|

Accelerated mass that strikes the body causing injury or death. (Examples are falling objects and projectiles.) |

Struck Against |

Injury to a body part as a result of coming into contact of a surface in which action was initiated by the person. (An example is when a screwdriver slips.) |

Temperature Extreme

|

Temperatures that result in heat stress, exhaustion, or metabolic slow down such as hypothermia. |

Visibility |

Lack of lighting or obstructed vision that results in an error or other hazard. |

Weather Phenomena

|

Self explanatory. |

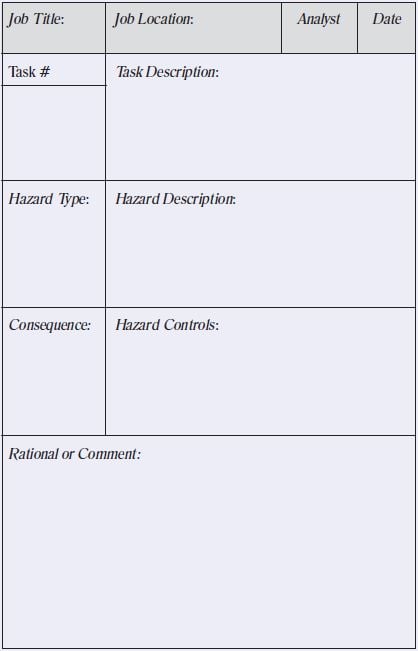

'Sample' Job Hazard Analysis