The Occupational Safety and Health Administration (OSHA) offers Outreach Training for 4 industries: Construction, General Industry, Maritime, and Disaster Site Work. OSHA has done well over the years to expand the reach of their programs to help workers become more knowledgeable about workplace hazards and their rights. Specifically, OSHA's Outreach Training Program provides training on the recognition, avoidance, abatement, and prevention of these workplace hazards.

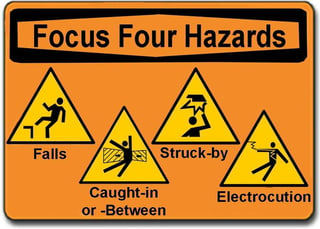

The construction industry deserves a little extra attention as it accounts for about 1 in 5 worker deaths. The Focus Four hazards (falls, struck by object, electrocution, and caught-in/between) are especially dangerous. In fact, according to OSHA, eliminating the Focus Four would save over 600 workers' lives in America each year.

Here are OSHA's top violations as they relate to the construction industry and how you can learn more about/avoid them.

Construction Top Violations

1926.501 - Fall Protection

1926.451 - Scaffolding

1926.1053 - Ladders

Fall Protection

Designed to protect employees on walking/working surfaces with an unprotected side or edge above 6 feet.

Top 5 sections cited:

1926.501(b)(13) - Residential construction.

1926.501(b)(1) - Unprotected sides/edges.

1926.501(b)(10) - Roofing work on low-slope roofs.

1926.501(b)(11) - Steep roofs.

1926.501(b)(4)(i) - Holes and skylights.

Scaffolding

Employers are bound to protect construction workers from falls and falling objects while working on or near scaffolding at heights of 10 feet or higher.

Top 5 sections cited:

1926.451(g)(1) - Each employee on a scaffold more than 10 ft above a lower level shall be protected from falling to that lower level.

1926.451(e)(1) - When scaffold platforms are more than 2 ft above or below a point of access. Cross braces shall not be used as a means of access.

1926.451(b)(1) - Working levels of scaffolds shall be fully planked or decked.

1926.451(g)(1)(vii) - Personal fall arrest systems or guardrails systems.

1926.451(g)(4)(i) - Guardrail systems shall be installed along all open sides and ends of platforms.

Ladders

Covers general requirements for all ladders.

Top 5 sections cited:

1926.1053(b)(1) - Portable ladder access.

1926.1053(b)(4) - Shall be used only for the purpose for which they are designed.

1926.1053(b)(13) - The top or top step of a step ladder should not be used as a step.

1926.1053(b)(16) - With structural defects.

1926.1053(b)(22) - An employee shall not carry any object or load that could cause the employee to lose balance and fall.

Now that you are aware of these heavily cited topics related to the construction industry, you can take steps in avoiding them. Your first might be to attend, or send your employees to attend a 10-hour OSHA training for construction. In this training, one will learn more about OSHA (and why we have the standards we do), health hazards in construction, personal protective and life-saving equipment, the Focus Four hazards (huge topic in construction), as well as some other construction related topics. For more information, or to attend our next OSHA 10 hour training for construction, click the button below. If you are in need of any other OSHA related safety training, visit our Training Services page to see what else Safety Training Services can offer you & your company.

According to the last data available (2013), there were 796 total fatalities in the construction industry. Let's round that off to 800, for the ease of digesting the numbers. Out of that number of fatalities, 294 were fall fatalities. Let's round that to 300 (again for ease of use in digestion of the numbers). So that gives us 300 fall fatalities out of 800 fatalities (within the construction industry), which means

According to the last data available (2013), there were 796 total fatalities in the construction industry. Let's round that off to 800, for the ease of digesting the numbers. Out of that number of fatalities, 294 were fall fatalities. Let's round that to 300 (again for ease of use in digestion of the numbers). So that gives us 300 fall fatalities out of 800 fatalities (within the construction industry), which means