Training is, by one definition, "a process by which someone is taught the skills that are needed for an art, profession, or job." Training has specific goals of improving one's capability, productivity, and performance in the specific area.

This means that prior to starting a job or a specific task; you must be trained to a level necessary for safe completion. The importance of this is paramount. It is not only cost effective to the company to practice safe procedures and train employees properly, but ultimately, we are putting lives at risk if training is not done or done incorrectly.

This means that prior to starting a job or a specific task; you must be trained to a level necessary for safe completion. The importance of this is paramount. It is not only cost effective to the company to practice safe procedures and train employees properly, but ultimately, we are putting lives at risk if training is not done or done incorrectly.

I want to explore the “importance of safety training” and why you should decide to invest your time and money into getting properly trained.

The first and most important reason: Reduce accidents.

This alone should trigger instantly as a ‘must.’ The reason from an individual’s standpoint should be obvious; accidents can too easily lead to death. That’s it, case closed. No more work, no more family, nothing. And not to mention the aftermath that someone else will have to deal with. This is not to scare you, but more so to shed light on the fact that reducing accidents is simply a must. In fact, many “accidents” aren’t accidents at all. They are operator related. We may label them as an accident, but if the operator truly knew the machine/job they were doing, and the safest way to do it, they would be able to be avoid the hazards entirely. Most ‘accidents’ are 100% preventable.

This brings me to the reasoning from a company standpoint. Yes, of course an individual would want safety training and I’m sure companies would see the importance of it. But I’m not writing this to discuss hypotheticals. The truth is, it is more often than not, the company that decides whether or not to send employees to training. And another fact is that I read about employees getting hurt or worse almost every day in various industries and so much of this can be prevented by simply conducting safety training properly. If the company cannot provide this safety training, they must recognize the dire importance (especially in high hazard workplaces) and inquire into a quality safety training company. Again, this is real world we are talking about and therefore time and money are something many companies need to factor into the equation before they can reach the result. Many companies see those two things as the main factor or deterrent in their choice. Understandably, I would like to take it further than just the cost of the training, or the cost of the employee’s time to take it. Let’s look at the REAL cost of an accident and then weigh that against the (at that point) seemingly meager price of quality safety training.

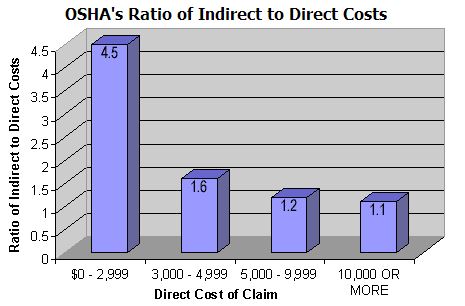

Accidents are more expensive than many people realize because in addition to the direct costs (medical costs, compensation payments, etc.) you’ll have indirect costs. Indirect costs include, but are not limited to: costs to train a replacement worker, repairing damaged property, cost to investigate the accident. Now take it one step further and you’ll see even more costs that aren’t as obvious, such as added administrative time, lower morale, increased absenteeism, and poorer customer relations. These costs are sometimes much higher than the simple direct costs. In fact, OSHA states that the lower the direct costs of an accident, the higher the ratio of indirect to direct costs. The more accidents that occur in a workplace, the higher the costs — both in increased insurance premiums and greater indirect costs.

(medical costs, compensation payments, etc.) you’ll have indirect costs. Indirect costs include, but are not limited to: costs to train a replacement worker, repairing damaged property, cost to investigate the accident. Now take it one step further and you’ll see even more costs that aren’t as obvious, such as added administrative time, lower morale, increased absenteeism, and poorer customer relations. These costs are sometimes much higher than the simple direct costs. In fact, OSHA states that the lower the direct costs of an accident, the higher the ratio of indirect to direct costs. The more accidents that occur in a workplace, the higher the costs — both in increased insurance premiums and greater indirect costs.

If you would like to see more specifics of estimating and calculating the true cost of workplace injuries, Safety Management Group has an easy to use calculator found by clicking here.

More reasons to consider the importance of safety training:

Training can improve business performance, profit and staff morale.

-

In addition to reducing accidents, training your staff can result in safer work practices and even productivity improvements.

-

By training your employees or allowing time for training, you demonstrate that you value them enough to invest in them. This improves loyalty and retention, with retention being the benefit for you.

-

They acquire new skills, increasing their contribution to the business and building their self-esteem

Remember, action is always faster than reaction. Therefore, it is better to be proactive rather than reactive when it comes to safety and/or safety training. If you take the time to analyze then you have a much higher chance that nothing will happen. Hopefully, this has motivated you take action! To seek out quality safety training now, as opposed to waiting until OSHA has stepped in or even worse, waiting until a workplace injury or death occurs.

Flexibility and Mobility - training firms can conduct training in most venues and locales regardless of distance or accommodations. They are focused on getting the training done correctly and not on the “sacrifice” they are making for the company in terms of their other duties. Contracted Trainers carry literally suitcases of training equipment and materials that allows them to conduct a session in almost any situation, geographic location or audience.

Flexibility and Mobility - training firms can conduct training in most venues and locales regardless of distance or accommodations. They are focused on getting the training done correctly and not on the “sacrifice” they are making for the company in terms of their other duties. Contracted Trainers carry literally suitcases of training equipment and materials that allows them to conduct a session in almost any situation, geographic location or audience.