We're finally here! Welcome back to the 4th (and final) part of Safety Training Service's web series on general office safety! If you haven't had a chance to read parts 1 through 3, you may find them here:

Part One | Part Two | Part Three

According to OSHA, the majority of general industry accidents come in the form of slips, trips, and falls. These can result in back injuries, strains and sprains, contusions, and fractures.

OSHA also states that 15% of all accidental deaths are caused by slips, trips, and falls. In fact, they are second only to motor vehicles as a cause of fatalities. The standards for slips, trips, and falls are in the Code of Federal Regulations, under the heading "Subpart D" or 29 CFR 1910.22-30. This covers cause and prevention and included are housekeeping, ladder safety, floor openings and stairways.

Slips can occur when floors or other working surfaces become slippery due to wet or oily processes, floor cleaning, leaks, or from materials and debris left in walkways.

Slips can occur when floors or other working surfaces become slippery due to wet or oily processes, floor cleaning, leaks, or from materials and debris left in walkways.

Trips can occur due to uneven floor or working surfaces, protruding nails and boards, from stretched carpet or bunched floor mats intended to prevent slipping, from holes or depressions in working surfaces, and from step-risers that are not uniform in height.

Falls can be a result of both slips and trips. In addition, improper ladder maintenance/use and stairways or elevated working surfaces that are not designed properly can result in a fall accident.

What can cause slips, trips, and falls? Just to name a few, ice, wet spots, grease, polished floors, loose flooring or carpeting, uneven walking surfaces, clutter, electrical cords, open desk drawers/filing cabinets, damaged ladder steps.

- Keep walkways and stairs clear of scrap and debris

- Coiling up extension cords, lines, and hoses when not in use

- Keeping electrical and other wires out of the way

- Wearing lug soles in icy weather

- Clearing parking lots, stairs, and walkways in snowy weather

- Using salt/sand as needed

- Where wet or potentially wet working conditions, maintain proper drainage and provide false floors, platforms, nonslip mats or floor surfaces, or other dry standing places (where practicable)

- Create nonslip surfaces in slippery areas by using no-skid waxes and/or grit-coated products

- Use slip-resistant footwear

- If a floor or working surface becomes wet, clean promptly and frequently

- Use/provide warning signs for wet floors

- Power/electrical cords that must cross walkways/aisles should be taped down (it is preferable to avoid this entirely by using floor plugs, if possible)

- Walkways/aisles should be kept clear at all times and should be wide enough for easy movement

- Carpet bulges or bunched up areas of carpet should be re-laid or stretched to prevent tripping

- Keep cabinets/drawers closed

- Eliminate clutter, obstructed work areas, and uneven floor surfaces

- Good lighting should be provided for all halls and stairwells, especially at night

- Stairs should have proper handrails and treads/risers should be maintained with slip-resistant surfaces, if possible

- Use handrails on stairs, don't run, and request help managing bulky loads. You must have an unobstructed view of the stairs

- Elevated storage and work surfaces should have guardrails, toe boards, and a permanent means of access

- Floor drains, pits, or any other floor opening should be covered or protected with guardrails

- Ladders should be properly maintained and have evenly spaced rungs and nonslip safety feet to reach items.

- Stools, chairs, boxes are NOT substitutes for ladders!

- Employees should be properly trained in the safe use of ladders

Ergonomics in the workplace

- Primary Zone - This will be all the items you use on a very regular basis. This is the distance from your elbow to your hand. Such items may include your keyboard, mouse, and a notepad.

- Secondary Zone - These are the items within your arm's reach. Position the items that you use often but not as frequently as the ones in your primary zone. What do you use periodically? Maybe its your phone, calculator, and some trays for paperwork.

- Reference Zone - This is for your least-often used items. This zone is outside your arm's reach. Could be whatever you personally use least, it might be a utensil cup, plant(s), clock or even photos.

Ergonomics includes adjustments to your "body" as well. Listed below is 10 things to adjust, if necessary, to "you" in order to enhance your comfort at in your workplace.

- Take frequent recovery pauses from typing.

- Maintain a straight wrist position when typing.

- Avoid resting on your wrists while typing.

- Use a light touch on mouse and keys while typing.

- Maintain good health habits.

- Adjust keyboard and chair height to keep wrists straight.

- Place mouse next to the keyboard.

- Keep your feet on the floor or use a footrest for support.

- Support your lower back and use armrests, if possible, to comfortably support your arms.

- Throughout the day, adjust your chair positions, your posture and vary your tasks.

If you are using a laptop computer, optimizing its work surface, ergonomically speaking, can be a bit tricky. A special base that helps adjust the height and angle of a laptop monitor for a healthier and more comfortable work experience has been developed for exactly this situation.

- Blink more! We blink only 1/5th as much looking at a computer monitor as reading a newspaper. Try lowering your monitor so you are looking down, in order to help promote this.

- Move your monitor back a little bit. Our eyes are adapted for distance vision. Yet, most office work is done close to our eyes. Compensate for this by moving your chair periodically or adjust the distance/height of your monitor.

- Have a bigger monitor? Try increasing the size of your font/images. And of course, move back further from the screen.

- Try moving documents/items on your screen to different sides. Right eye dominant? Left eye? Try moving your email/documents to the left or the right and see if that is more comfortable for you.

- What about after all these tips, you still seem to have some discomfort? Try some glasses or seeing an eye care specialist. Seriously, its not the 70's/80's anymore, that stigma of the nerdy kid with glasses is gone! Get a sweet pair for the sole purpose of reading/working with computer monitors or similar devices. I am wearing mine as I type this, but use them generally just for this purpose and take them off when not working.

|

Fluorescent lights? |

Harsh, excessively bright. Causes eye strains and glare. |

|

Too little lighting? |

Eye strain with paper documents, "gloomy" work atmosphere. |

|

Windows? |

Can cause lighting/glare problems, but given the choice most people would probably prefer having natural light and a view. |

|

Direct Sunlight? |

Not adjustable, unfortunately. Can be much brighter then what is actually needed. |

Two things I would like to mention, but won't spend as much time on is temperature/humidity and noise.

- Reduce or eliminate at the source whenever possible.

- Maintain equipment to prevent noisy malfunctions.

- Isolate or enclose equipment that generates noise even when it's in good repair.

- Have conference rooms available for meetings and conversations.

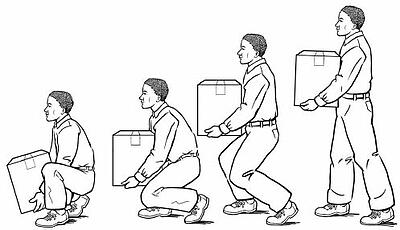

Lifting

If lifting is included in an employee's tasks, then the employer is obligated to teach the employee the best way to lift. You may choose to have safety training for your employees covering ergonomics and lifting limits. Ultimately employees should know how to properly lift, when to get help, and when to use mechanical means rather than manually lifting an object.

If lifting is included in an employee's tasks, then the employer is obligated to teach the employee the best way to lift. You may choose to have safety training for your employees covering ergonomics and lifting limits. Ultimately employees should know how to properly lift, when to get help, and when to use mechanical means rather than manually lifting an object.- Keep object close to the body, don't reach out for an object.

- Move slowly and purposefully, don't jerk or twist.

- Feet should be shoulder width apart.

- Lift with your legs, not your back!

- Keep the back in a neutral position, bending should be done at the hips and knees. Keep knees slightly bent, never locked straight.

Procedures for reporting fires and other emergencies.

Procedures for reporting fires and other emergencies. for hazardous materials, potential ignition sources and their control, and the type of fire protection equipment necessary to control each major hazard.

for hazardous materials, potential ignition sources and their control, and the type of fire protection equipment necessary to control each major hazard.

PPE is designed to protect you from hazards related to your work.

PPE is designed to protect you from hazards related to your work.  Global Harmonization changed the label from MSDS to SDS, with a permanent change that came in 2015. OSHA requires that these data sheets be available to employees for potentially harmful substances handled in the workplace. Basically, these are intended to provide the workers and also emergency personnel the information necessary to safely handle/work with said substances. This information may include physical and/or chemical data and format may differ (currently there is no official way to format SDS). Below are some examples of what information you may find on SDS.

Global Harmonization changed the label from MSDS to SDS, with a permanent change that came in 2015. OSHA requires that these data sheets be available to employees for potentially harmful substances handled in the workplace. Basically, these are intended to provide the workers and also emergency personnel the information necessary to safely handle/work with said substances. This information may include physical and/or chemical data and format may differ (currently there is no official way to format SDS). Below are some examples of what information you may find on SDS.

ALWAYS read/follow the labels on the ladder. Until the climber is familiar with this information, they are not considered "adequately" trained!

ALWAYS read/follow the labels on the ladder. Until the climber is familiar with this information, they are not considered "adequately" trained!