In 1996, the National Safety Council (NSC) established June as National Safety Month to increase awareness of key safety issues. The idea is to decrease the number of unintentional injuries and deaths. NSC is also aligned with government agencies, such as OSHA, to help strengthen the influence of compliance in workplace safety.

increase awareness of key safety issues. The idea is to decrease the number of unintentional injuries and deaths. NSC is also aligned with government agencies, such as OSHA, to help strengthen the influence of compliance in workplace safety.

The 2014 theme for National Safety Month is “Safety: It takes all of us.” Each week of National Safety Month focuses on a specific safety venue: workplace, traffic, home, and community. For example, the 2014 safety issues are as follows:

Prevent prescription drug abuse

Prescription drug abuse is the intentional use of a medication without having a prescription for it. This also includes using prescription drugs in ways other than intended or prescribed. Prescription drug abuse has become a serious safety issue. As of 2013, it was the second most widespread drug issue in the United States.

Here are some tips to stay safe with your medications:

Keep your meds in a secure place. Leaving them out in plain view can lead to theft.

Keep your meds in a secure place. Leaving them out in plain view can lead to theft.- Keep track of your medicine. Know how many pills you have, and what they look like.

- Don’t share any medications.

- Dispose of your meds correctly.

- Keep meds in original container.

- Remove your information

- For pills, add water/soda to dissolve them; for liquids, use cat litter or dirt.

- Close and secure with duct tape.

- The disguised & sealed container can now be thrown out with the normal trash.

Stop slips, trips, and falls

Some of the worst yet most common type of office injuries in the workplace, but they are also the easiest to correct.

Common causes of slips are:- wet or oily surfaces

- occasional spills

- weather hazards

- loose, unanchored rugs or mats

- flooring or other walking surfaces that do not have same degree of traction in all areas

- obstructed view

- poor lighting

- clutter in your way

- wrinkled carpeting

- uncovered cables

- bottom drawers not being closed

- uneven (steps, thresholds) walking surfaces

Clean all spills immediately

Clean all spills immediately- Mark spills and wet areas

- Mop/sweep debris from floors

- Remove obstacles from walkways and always keep them free of clutter

- Secure mats, rugs and carpets that do not lay flat

- Always close file cabinet or storage drawers

- Cover cables that cross walkways

- Keep working areas and walkways well lit

- Replace used light bulbs and faulty switches

Be aware of your surroundings

Contact with objects is the second leading cause of cases with days away from work. This includes:

- Being struck against an object

- Struck by an object

- Caught in an object or equipment

- Caught in collapsing material

Here are some tips to help prevent injury from contact with objects:

- Neatly store loose materials

- Secure items that are stored at a height

- Store heavy objects close to the floor

- Open one filing cabinet drawer at a time to prevent a tip-over

- Wear the proper PPE for your environment

- Always walk behind moving equipment, if possible

- Never obstruct your vision by overloading moving equipment

- Only operate equipment that you are properly trained to use

- Make sure all the safety devices on your equipment are in good working order before use

- Use extra caution around corners and near doorways

Put an end to distracted driving

Driving while using a cell phone has been a part of our culture. What, to some, can be seen as a necessity, others realize how dangerous it really is. Whether its business or personal, we need to remind ourselves that this is a potentially life-altering activity. Here are some tips from the National Safety Council about how to break this bad habit.

Schedule calls for times when you will not be driving.

Schedule calls for times when you will not be driving.- Tell other people not to call you when they know you are driving.

- Plan your day ahead of time so you won’t need to use a cell phone while driving.

- Change your voicemail greeting to something like: “Hi, you’ve reached (insert name). I’m either away from my phone or I’m driving. Please leave me a message.” You can also let callers know approximately what time you will be available again so they know when to expect to hear from you.

- If a ringing phone is too tempting, get in the habit of silencing your phone before you start to drive, or lock it in the trunk or glove box.

- Work with your coworkers and family members on breaking the habit and hold each other accountable.

- Allow enough time during your commute for stops so you can pull over and park in a safe location to check email and voicemail messages.

- Consider using call-blocking technology when you are driving.

- Remember, hands-free devices don’t make you safer—while they allow for one more hand to be placed on the steering wheel, they do not reduce cognitive distraction to the brain.

Remember, accidents are preventable. There is almost always no reason for them other than a lack of training. Be sure to take an appropriate amount of time daily, weekly, monthly, annually to have safety meetings, training days, etc. If you are interested or have any questions regarding safety training or any question on frequency of training, contact STS.

Once a fire extinguisher has been selected and placed in compliance with OSHA/NFPA standards, you then need to know how to use it. Training for yourself and/or employees is a very important step and should not be overlooked. The unfortunate reality, as you’ll see further below via the NFPA stats, is that fires happen all the time. Having properly learned how to use an extinguisher can save someone’s life. Below you find training specifics, as presented by the 1910.157 OSHA standard guidelines, as well as a few tips for how to engage employees further with hands-on training.

Once a fire extinguisher has been selected and placed in compliance with OSHA/NFPA standards, you then need to know how to use it. Training for yourself and/or employees is a very important step and should not be overlooked. The unfortunate reality, as you’ll see further below via the NFPA stats, is that fires happen all the time. Having properly learned how to use an extinguisher can save someone’s life. Below you find training specifics, as presented by the 1910.157 OSHA standard guidelines, as well as a few tips for how to engage employees further with hands-on training.

The 2012 U.S. fire loss clock a fire department responded to a fire every 23 seconds. One structure fire was reported every 66 seconds.

The 2012 U.S. fire loss clock a fire department responded to a fire every 23 seconds. One structure fire was reported every 66 seconds.

SERIOUS:

SERIOUS:

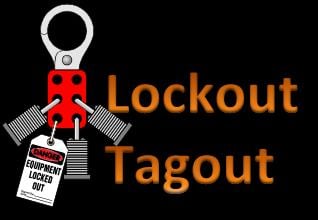

Lockout/Tagout

Lockout/Tagout Fall Protection

Fall Protection

Luckily for us, this is a simple 7 step process that will become routine in time. The first two things you must know before starting an inspection of your fire extinguishers are:

Luckily for us, this is a simple 7 step process that will become routine in time. The first two things you must know before starting an inspection of your fire extinguishers are: must prevent the powder from settling. Go ahead, give it a shake. While its in your hands, is it any lighter than usual or than you'd expect? Call your servicing company (or

must prevent the powder from settling. Go ahead, give it a shake. While its in your hands, is it any lighter than usual or than you'd expect? Call your servicing company (or Now that the extinguisher is placed correctly and the label is facing outward, check the pin or safety seal. It should still be intact; if not, you should replace the fire extinguisher.

Now that the extinguisher is placed correctly and the label is facing outward, check the pin or safety seal. It should still be intact; if not, you should replace the fire extinguisher. Congratulations, your monthly inspection is complete. Be sure to sign your initials on the tag when it has space for monthly inspections. This verifies that the extinguisher is up-to-date and also proves to OSHA (if need arises) that a monthly inspection has been performed.

Congratulations, your monthly inspection is complete. Be sure to sign your initials on the tag when it has space for monthly inspections. This verifies that the extinguisher is up-to-date and also proves to OSHA (if need arises) that a monthly inspection has been performed.

This means that prior to starting a job or a specific task; you must be trained to a level necessary for safe completion. The importance of this is paramount. It is not only cost effective to the company to practice safe procedures and train employees properly, but ultimately, we are putting lives at risk if training is not done or done

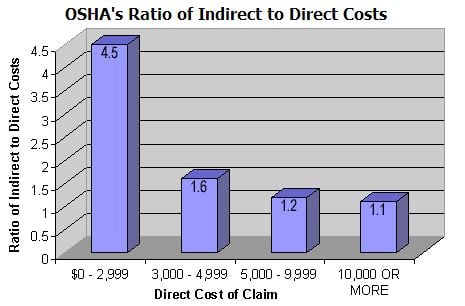

This means that prior to starting a job or a specific task; you must be trained to a level necessary for safe completion. The importance of this is paramount. It is not only cost effective to the company to practice safe procedures and train employees properly, but ultimately, we are putting lives at risk if training is not done or done  (medical costs, compensation payments, etc.) you’ll have indirect costs. Indirect costs include, but are not limited to: costs to train a replacement worker, repairing damaged property, cost to investigate the accident. Now take it one step further and you’ll see even more costs that aren’t as obvious, such as added administrative time, lower morale, increased absenteeism, and poorer customer relations. These costs are sometimes much higher than the simple direct costs. In fact, OSHA states that the lower the direct costs of an accident, the higher the ratio of indirect to direct costs. The more accidents that occur in a workplace, the higher the costs — both in increased insurance premiums and greater indirect costs.

(medical costs, compensation payments, etc.) you’ll have indirect costs. Indirect costs include, but are not limited to: costs to train a replacement worker, repairing damaged property, cost to investigate the accident. Now take it one step further and you’ll see even more costs that aren’t as obvious, such as added administrative time, lower morale, increased absenteeism, and poorer customer relations. These costs are sometimes much higher than the simple direct costs. In fact, OSHA states that the lower the direct costs of an accident, the higher the ratio of indirect to direct costs. The more accidents that occur in a workplace, the higher the costs — both in increased insurance premiums and greater indirect costs.

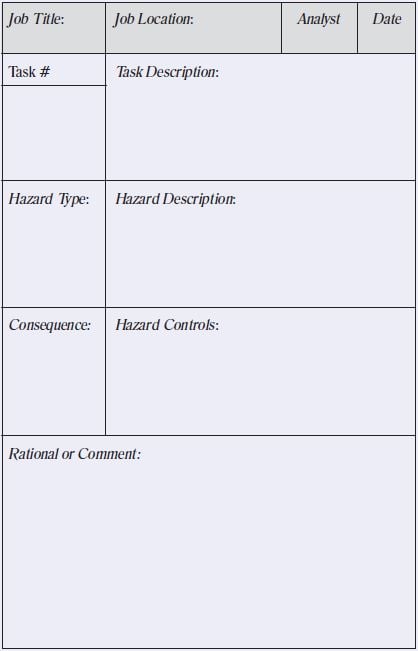

A job hazard analysis is likely to result in:

A job hazard analysis is likely to result in: How to identify hazards

How to identify hazards

Falls

Falls

So what should you do, now armed with this knowledge? Well, first thing is get up and simply take a look around your office/plant/factory. Do you see any of these standards violated? In the safety world, if you think you have a problem....chances are you do! If you do not know you have violations or do not know how to look for them, that's perfectly understandable--you are not alone. This is where Safety Training Services can help!

So what should you do, now armed with this knowledge? Well, first thing is get up and simply take a look around your office/plant/factory. Do you see any of these standards violated? In the safety world, if you think you have a problem....chances are you do! If you do not know you have violations or do not know how to look for them, that's perfectly understandable--you are not alone. This is where Safety Training Services can help! Lockout/tagout is required when the unexpected energization or start up (or release of stored energy) of machines, equipment or prime movers could injure workers during cleaning, repairing, servicing, setting-up, adjusting and un-jamming.

Lockout/tagout is required when the unexpected energization or start up (or release of stored energy) of machines, equipment or prime movers could injure workers during cleaning, repairing, servicing, setting-up, adjusting and un-jamming.

Circuit breakers

Circuit breakers