"The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement."

In many parts of the United States there are as many standby high angle or confined space rescue teams as there are confined spaces. How do you choose the right team for your rescue plan? Does each team provide the same quality, competency, and proficiency? No matter if you have worked with the same rescue plan for the last ten years, or you are planning for rescue from your first confined space, here are three things you need to know about choosing a rescue team:

1. NFPA 350 states how quickly your team should be able to rescue

Depending on the hazards and design of the confined space, NFPA 350 Guide for Safe Confined Space Entry and Work specifies how quickly your designated rescue team should be able to react and respond to an emergency within your confined space. NFPA 350 categorizes spaces based on potential or actual hazards

- Tier I – No recognized hazard but could require technical rescue should a worker become incapacitated

- Rescue is available to respond within five minutes to the site and is capable of setup and rescue entry within 15 minutes

- Tier II – Non-life-threatening hazards requiring rapid intervention

- Rescue is on site, equipped for safe entry and rescue. Capable of setup and rescue entry within 12 to 15 minutes of incident

- Tier III – Life-threatening hazards requiring immediate intervention. Actual or potential IDLH condition

- Rescue is fully setup and capable of rescue entry within two minutes of incident. Rescue team should be dedicated to this singular entry with no other responsibilities

2. NFPA 350 states how many people should be on the rescue team

In the industrial setting we often see is a cookie cutter response to confined space rescue needs – always sending the same number of people to the standby site, no matter the hazards of the space and the duties of the rescuers at the scene. NFPA 350 once again shows us what we need:

-

If the confined space has no obstructions OR entanglement hazards AND entrant is properly attached to a retrieval system THEN one rescuer is needed to perform a non-entry rescue.

-

If the confined space has no obstructions or entanglement hazards, the entrant is not attached to a retrieval system, no potential atmospheric hazards exist, and vertical extraction is not required THEN three rescuers are needed to perform an emergency entry to effect rescue: 1 Rescue Attendant, 2 Rescue Entrants

-

If the confined space has obstructions or entanglement hazards, the entrant is not attached to a retrieval system, there is no potential for atmosphere hazards, and vertical extraction is required THEN five rescuers are needed to perform an emergency entry to effect rescue: 1 Rescue Attendant, 2 Rescue System Operations (with assistance from plant personnel), and 2 Rescue Entrants

-

If the confined space has obstructions or entanglement hazards, the entrant is not attached to a retrieval system, the potential for atmosphere hazards exist, supplied air respirator cannot be used (requiring SCBA, and vertical extraction is not required THEN five rescuers are needed to perform an emergency entry to effect rescue: 1 Rescue Attendant, 2 Person entry team, 2 Rescue Entrants

3. Relying on 911 is not good enough

The OSHA Permit-Required Confined Space standards provides criteria for rescue teams in Non-Mandatory Appendix F – Rescue Team or Rescue Service Evaluation Criteria. From Appendix F:

“The employer should meet with the prospective rescue service to facilitate the evaluations…At a minimum, if an off-site rescue service is being considered, the employer must contact the service to plan and coordinate the evaluations required by the standard. Merely posting the service's number or planning to rely on the 911 emergency phone number to obtain these services at the time of a permit space emergency would not comply with paragraph (k)(1) of the standard.”

It is not the intention to state that a fire department is incapable or will refuse to respond because you did not meet with them prior to your confined space work. As of December 2017 there were over 27,000 fire departments in the United States. (source) and each one of those departments can have vastly different capabilities when compared to the next.

You may have a full-time, on-call, or volunteer department. Each one will have different response times and each one will have different levels of rescue service – some having no confined space ability, and will rely on a neighboring department or county rescue team. When called, the fire department will always respond, but without a conversation, you may be expecting a service that is unavailable. Remember that the fire service in your community is on a first-come first-serve basis, the first person to have an emergency in your community will receive service. The second person or place to have an emergency will receive service but it may be coming from the other side of the city or from the next closest city if your department is called elsewhere.

For additional resources visit OSHA RESCUE SERVICE REQUIREMENTS where you can view the OSHA and NFPA standards, and download the Rescue Team Evaluation Tool.

without using an extraordinary amount of time, it is an acceptable method. The goal here is to be proficient in whatever you do and be capable of doing it and 3 A.M. when called to a rescue.

without using an extraordinary amount of time, it is an acceptable method. The goal here is to be proficient in whatever you do and be capable of doing it and 3 A.M. when called to a rescue.

While there are countless rescue classes, instructors,

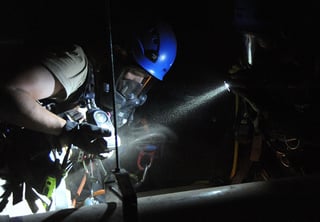

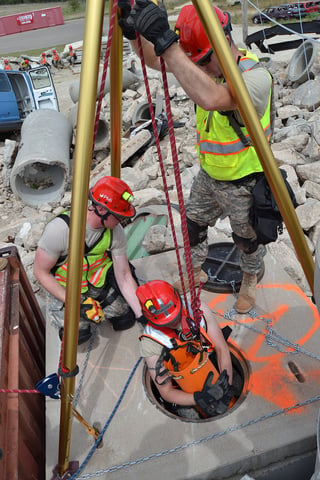

While there are countless rescue classes, instructors,  to make entry in the event of an emergency will require countless hours of training to maintain proficiency in patient care, personal protective equipment, atmospheric monitoring, and rescue techniques. Additionally, there should be training which addresses the stressful nature of rescue when the rescuer personally knows the coworker needing rescue, as well as any additional hazards now present within the space. Confined spaces are hazardous at the start of a work day, if you have an emergency within the space it is multiplying the complexity of the incident. OSHA requires that entry rescue teams perform at least one rescue per year. The following statement may sound extreme – do you want a rescuer entering a confined space to rescue you if that rescuer has only performed one rescue? Your rescue team now has the need to perform under stressful conditions with a variety of equipment, within a variety of spaces, using one of hundreds of techniques to remove the entrant having an emergency.

to make entry in the event of an emergency will require countless hours of training to maintain proficiency in patient care, personal protective equipment, atmospheric monitoring, and rescue techniques. Additionally, there should be training which addresses the stressful nature of rescue when the rescuer personally knows the coworker needing rescue, as well as any additional hazards now present within the space. Confined spaces are hazardous at the start of a work day, if you have an emergency within the space it is multiplying the complexity of the incident. OSHA requires that entry rescue teams perform at least one rescue per year. The following statement may sound extreme – do you want a rescuer entering a confined space to rescue you if that rescuer has only performed one rescue? Your rescue team now has the need to perform under stressful conditions with a variety of equipment, within a variety of spaces, using one of hundreds of techniques to remove the entrant having an emergency.

A permit required confined space is a confined space that requires a special permit to enter. These usually contain (or have the potential to contain) a hazardous atmosphere, an engulfment or entrapment hazard, or physical hazards. If any other serious safety or health hazard are present, it may also be classified as permit-required. Some companies even take a step further than the OSHA requirements and choose to treat every confined space onsite as a permit required confined space and follow all processes and procedures pertaining to those types of entries.

A permit required confined space is a confined space that requires a special permit to enter. These usually contain (or have the potential to contain) a hazardous atmosphere, an engulfment or entrapment hazard, or physical hazards. If any other serious safety or health hazard are present, it may also be classified as permit-required. Some companies even take a step further than the OSHA requirements and choose to treat every confined space onsite as a permit required confined space and follow all processes and procedures pertaining to those types of entries.