As you may have already heard, OSHA has developed a new construction standard for confined spaces. That standard, 29 CFR 1926 Subpart AA, will replace the previous single training requirement for confined space work and instead be a comprehensive standard that is similar with the general industry confined space standard, but will address construction specific hazards and will improve enforceability of the new requirements.

In this article, I will discuss a few more specifics from this new standard so as to raise awareness of the requirements, the hazards specific to the construction industry, and even touch on a bit of information about the standard covering permit-required confined spaces in general industry so you may see how the two are similar but different enough to warrant necessary training & knowledge specific to one or the other.

The new rule differs from the previous construction rule in that employers must now determine what kinds of confined spaces their workers are in,what hazards are present or could be present there, how to make those hazards safe, what training is required for workers, and how to rescue those workers if something were to go wrong.

Confined Spaces in Construction: Crawl Spaces and Attics

Crawl Spaces and attics, under the new construction standard, can be classified as confined spaces and permit-required confined spaces. Many times these spaces have one way in or out, are small but large enough for a person to enter, and are not generally built for continuous occupancy. With these facts, they are the very definition of confined spaces. If you are, for example, spraying in the attic, one could be exposed to hazardous atmospheres or low oxygen levels. Confined space hazards can include:

- Atmospheric hazards

- Electrocution

- Standing water

- Poor lighting

- Structural collapse

- Asbestos insulation

- Heat stress

- Mechanizal hazards

- Slip, trip, fall hazards

Confined Spaces in Construction: Pits

Pits can also be classified as confined spaces and permit-required confined spaces. Sump pits, valve pits, electrical pits, elevator pits, steam pits, etc. are entered for renovation work, installing equipment or cables, or simply just to verify the status of something in said pit. By changing the entry or exit or even changes in the air flow can allow these spaces to be classified as confined spaces or re-classify as a permit-required.

Confined Spaces in Construction: Sewer Systems

Sewer systems, whether sanitary, storm, or combined, are extensive and include many different components. Many, if not all, of these components can be classified as confined spaces. Of course, with some changes in the construction work, these can be permit-required as well. Continuous air monitoring is very important while working in sewer systems. Other hazards include:

- Atmospheric hazards

- Chemicals present

- Drowning or engulfment

- Electrocution

- Slips, trips, falls

- Falling objects

- High noise and/or low visibility

So what are the differences between the general industry & the construction rule? There are five new requirements that differ from the general industry rule. You can find them below:

- More detailed provisions requiring

coordinated activities when there are multiple employers at the worksite. This will ensure hazards are not introduced into a confined space by workers performing tasks outside the space.

coordinated activities when there are multiple employers at the worksite. This will ensure hazards are not introduced into a confined space by workers performing tasks outside the space. - Requiring a competent person to evaluate the work site and identify confined spaces, including permit spaces.

- Requiring continuous atmospheric monitoring whenever possible.

- Requiring continuous monitoring of engulfment hazards.

- Allowing for the suspension of a permit, instead of cancellation, in the event of changes from the entry conditions listed on the permit or an unexpected event requiring evacuation of the space. The space must be returned to the entry conditions listed on the permit before re-entry.

In addition, OSHA has added provisions to the new rule that clarifies existing requirements in the general industry standard.

- Requiring that employers who direct workers to enter a space without using a complete permit system prevent workers' exposure to physical hazards through elimination of the hazard or isolation methods such as lockout / tagout.

- Requiring that employers who are relying on local emergency services for emergency services arrange for responders to give the employer advance notice if they will be unable to respond for a period of time (because they are responding to another emergency, attending department-wide training, etc.)

- Requiring employers to provide training in a language and vocabulary that the worker understands.

Finally, several additional definitions have been added to the construction rule. For example:

- Entry employer - The employer who directs workers to enter a space.

- Entry rescue - Clarifies the differences in the types of rescue employers can use.

The final rule will become effective on August 3, 2015.

Get the jump on the new rule(s) by signing up for safety training courses through STS. Whether you come to our Highland facility or we come to yours, we can assist you and your employees in OSHA compliance throughout your workplace. We conduct training, sell/rent equipment, provide rescue teams, and are even available as an on-call consultant ready to assist you with any OSHA-related issues. For more information, simply contact us below and let us know how we can help you.

Get the jump on the new rule(s) by signing up for safety training courses through STS. Whether you come to our Highland facility or we come to yours, we can assist you and your employees in OSHA compliance throughout your workplace. We conduct training, sell/rent equipment, provide rescue teams, and are even available as an on-call consultant ready to assist you with any OSHA-related issues. For more information, simply contact us below and let us know how we can help you.

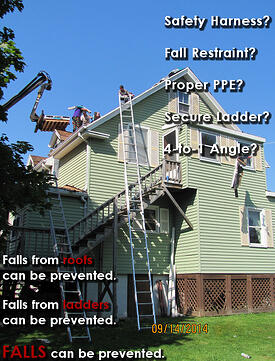

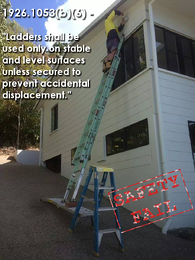

According to the last data available (2013), there were 796 total fatalities in the construction industry. Let's round that off to 800, for the ease of digesting the numbers. Out of that number of fatalities, 294 were fall fatalities. Let's round that to 300 (again for ease of use in digestion of the numbers). So that gives us 300 fall fatalities out of 800 fatalities (within the construction industry), which means

According to the last data available (2013), there were 796 total fatalities in the construction industry. Let's round that off to 800, for the ease of digesting the numbers. Out of that number of fatalities, 294 were fall fatalities. Let's round that to 300 (again for ease of use in digestion of the numbers). So that gives us 300 fall fatalities out of 800 fatalities (within the construction industry), which means

should stay vigilant about avoid certain things if we have previous issues, did you know that there are certain foods & food ingredients that influence heart behaviors? For example, hydrogenated oils are believed to be not good for the heart. These are generally found in chips, crackers, store bought pastries (things like doughnuts, muffins, etc.), and other baked foods. These hydrogenated oils increase cholesterol in the body which in turn, increases risk of heart attack. If you have already experienced a heart attack, these would be foods to generally avoid in order to remain healthy in the long term.

should stay vigilant about avoid certain things if we have previous issues, did you know that there are certain foods & food ingredients that influence heart behaviors? For example, hydrogenated oils are believed to be not good for the heart. These are generally found in chips, crackers, store bought pastries (things like doughnuts, muffins, etc.), and other baked foods. These hydrogenated oils increase cholesterol in the body which in turn, increases risk of heart attack. If you have already experienced a heart attack, these would be foods to generally avoid in order to remain healthy in the long term.

necessary (AED is great too!)

necessary (AED is great too!)

cardiac arrest, as well as decipher the differences between them. As I stated earlier, in addition to bringing up awareness of the two, we will also discuss the symptoms, signs, and how to help others during an incident involving these heart problems.

cardiac arrest, as well as decipher the differences between them. As I stated earlier, in addition to bringing up awareness of the two, we will also discuss the symptoms, signs, and how to help others during an incident involving these heart problems. If you are in a situation in which someone around you is experiencing what you believe to be a heart attack, you have about five minutes to call 911 (or other local emergency response number). This is because every minute is important for a heart attack victim. Having emergency services show with an ambulance is one of the best ways to handle the situation, the emergency responders and can give treatment as soon as they arrive, and treatment can continue in the ambulance rather than if you drove them to the hospital yourself.

If you are in a situation in which someone around you is experiencing what you believe to be a heart attack, you have about five minutes to call 911 (or other local emergency response number). This is because every minute is important for a heart attack victim. Having emergency services show with an ambulance is one of the best ways to handle the situation, the emergency responders and can give treatment as soon as they arrive, and treatment can continue in the ambulance rather than if you drove them to the hospital yourself.

A permit required confined space is a confined space that requires a special permit to enter. These usually contain (or have the potential to contain) a hazardous atmosphere, an engulfment or entrapment hazard, or physical hazards. If any other serious safety or health hazard are present, it may also be classified as permit-required. Some companies even take a step further than the OSHA requirements and choose to treat every confined space onsite as a permit required confined space and follow all processes and procedures pertaining to those types of entries.

A permit required confined space is a confined space that requires a special permit to enter. These usually contain (or have the potential to contain) a hazardous atmosphere, an engulfment or entrapment hazard, or physical hazards. If any other serious safety or health hazard are present, it may also be classified as permit-required. Some companies even take a step further than the OSHA requirements and choose to treat every confined space onsite as a permit required confined space and follow all processes and procedures pertaining to those types of entries.

As Americans we spend up to 90% of our time indoors and many of us spend much, if not most, of our working hours in an office environment. The Environmental Protection Agency (EPA) has conducted studies that show how indoor environments sometimes can have levels of pollutants that are actually higher than levels found outside.

As Americans we spend up to 90% of our time indoors and many of us spend much, if not most, of our working hours in an office environment. The Environmental Protection Agency (EPA) has conducted studies that show how indoor environments sometimes can have levels of pollutants that are actually higher than levels found outside. integrating three main strategies.

integrating three main strategies. Some pollutants can cause both short and long term health problems. For example, prolonged exposure to environmental tobacco smoke can cause lung cancer, and short term exposures can result in irritation and significant respiratory problems for some people, particularly young children.

Some pollutants can cause both short and long term health problems. For example, prolonged exposure to environmental tobacco smoke can cause lung cancer, and short term exposures can result in irritation and significant respiratory problems for some people, particularly young children.