As we close out May and therefore Electrical Safety Month, I wanted to share a bit of information for those not familiar with the training requirements for avoiding electrical hazards. Even if you are familiar with the requirements, allow this to serve as a quick reminder to verify that you are in compliance with your relevant OSHA standard.

For many of those in industry who face the risk of injury from electrical shock or other electrical hazards, you must be trained so that you are knowledgeable of these hazards and how to avoid them. Some occupations have a higher risk due to the nature of their job. In fact, OSHA has detailed out the typical occupational categories of employees that face a higher than normal risk of electrical accident. This includes the following:

- Blue collar supervisors*

- Electrical and electronic engineers*

- Electrical and electronic equipment assemblers*

- Electrical and electronic technicians*

- Electricians

- Industrial machine operators*

- Material handling equipment operators*

- Mechanics and repairers*

- Painters*

- Riggers and roustabouts*

- Stationary engineers*

- Welders

*Workers in these groups do not need to be trained if their work or the work of those they supervise does not bring them or the employees they supervise close enough to exposed parts of electric circuits operating at 50 volts or more to ground for a hazard to exist.

For those who are on this list, but do not follow the expection list just above, training may be a necessary need to assist these employees in avoiding electrical hazards and a knowledgeable understanding of the potential of this energy. As you may surmise, proper precautions must be taken to guard against these hazards. Too many employees, too often, are victims of injuries (or worse) because they fail to take these proper precautions to guard against such hazards. Failure to recognize the hazard of contact with energized electrical equipment can be a fatal mistake.

Necessary Training Requirements for Electrical Safety &

Avoiding the Risk of Electrical Shock:

29 CFR 1910.332

www.OSHA.gov

- Employees must be trained in and familiar with safe work practices that pertain to their job assignments or relate to their safety. [(b)(1-2)]

- Are qualified employees permitted to work on or near exposed energized parts? If so, be sure they are trained in the skills and techniques necessary to distinguish exposed live parts from other parts of electric equipment. [(b)(3)(i)]

- Qualified employees must be trained in the skills and techniques necessary to determine the nominal voltage of exposed live parts. [(b)(3)(ii)]

- Qualified employees must be trained in the clearance distances specified in the standard, and in the corresponding votages to which they will be exposed. [(b)(3)(iii)]

Qualified employees are those permitted to work on or near exposed energized parts. Those not not deemed qualified persons, but whom risk similar electrical hazards, shall also be trained in and familiar with any electrically related safety practices. The different training requirements for qualified and unqualified employees are outlined below for reference.

"Qualified" employees must (at a minimum) be able to:

- Identify live electrical parts

- Know their voltages

- Follow proper safety procedures for working on or near exposed live parts

- Know proper PPE to be used

- Know the importance of using insulating and shield materials as well as insulated tools

Training for "Unqualified" employees should cover (at a minimum):

- The risks of energized equipment

- How to protect themselves and others when they work around electricity

- What tasks can be done only by qualified workers

- To always respect warning signs and barriers designed to protect them from live parts

Once again, as Electrical Safety Month comes and goes with the month of May, there is no better time to access your electrical safety needs. If you are in need of either electrical safety training or arc flash training, or simply have a question regarding these topics, contact Safety Training Services today. We look forward to assisting you with your electrical safety & training needs!

According to 1910.120(e)(8) you should be covering the following:

According to 1910.120(e)(8) you should be covering the following:

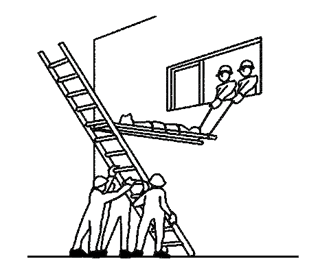

that caught my attention. In the video firefighters are using a ladder, backboard, and rope to move a patient from a roof or second floor to the ground. Depending where you were watching this video there were some great comments about thinking outside the box and using alternative methods to raise and lower patients. There were a large number of comments that were a little deceiving; comments attributed this rescue technique -- a ladder hinge -- to the fire department in the video. It's great to see this technique being used, but by today's standards it may be considered an old school technique. The ladder hinge gets overlooked or forgotten about when so many people are arguing over which friction device is the best. Depending on your location in the country or the world this technique is still taught, relied upon, and used regularly. For another take on a ladder hinge rescue see video link below.

that caught my attention. In the video firefighters are using a ladder, backboard, and rope to move a patient from a roof or second floor to the ground. Depending where you were watching this video there were some great comments about thinking outside the box and using alternative methods to raise and lower patients. There were a large number of comments that were a little deceiving; comments attributed this rescue technique -- a ladder hinge -- to the fire department in the video. It's great to see this technique being used, but by today's standards it may be considered an old school technique. The ladder hinge gets overlooked or forgotten about when so many people are arguing over which friction device is the best. Depending on your location in the country or the world this technique is still taught, relied upon, and used regularly. For another take on a ladder hinge rescue see video link below. - and you know their functions and responsibilities. Generally speaking, in a permit-required confined space operation the supervisor supervises, the entrant makes entry, and the confined space attendant does nothing but attend, right?

- and you know their functions and responsibilities. Generally speaking, in a permit-required confined space operation the supervisor supervises, the entrant makes entry, and the confined space attendant does nothing but attend, right? Safety within your organization should be viewed holistically--emphasizing the importance of the whole and the interdependence of its parts. While each part of your program, such as

Safety within your organization should be viewed holistically--emphasizing the importance of the whole and the interdependence of its parts. While each part of your program, such as  What about spills? What is your plan when the drums start leaking or the forklift driver pierces a tote? A bulk delivery driver is delivering a tanker full of hazardous materials to your site storage tanks, now the trailer is leaking, what can you do?

What about spills? What is your plan when the drums start leaking or the forklift driver pierces a tote? A bulk delivery driver is delivering a tanker full of hazardous materials to your site storage tanks, now the trailer is leaking, what can you do? for your site and equipment. There is no universal expiration date for hazmat response equipment and each piece of equipment is different. At all times manufacturer guidelines should be followed.

for your site and equipment. There is no universal expiration date for hazmat response equipment and each piece of equipment is different. At all times manufacturer guidelines should be followed.